- 100% RUST-FREE CONSTRUCTION. Dr.Fish Rotary Vise is constructed with Stainless Steel Stem, CNC Aluminum Arm, 40Cr steel Jaws, and Aluminum C-Clamp. Every component is manufactured aiming to withstand 10 years of frequently tying.

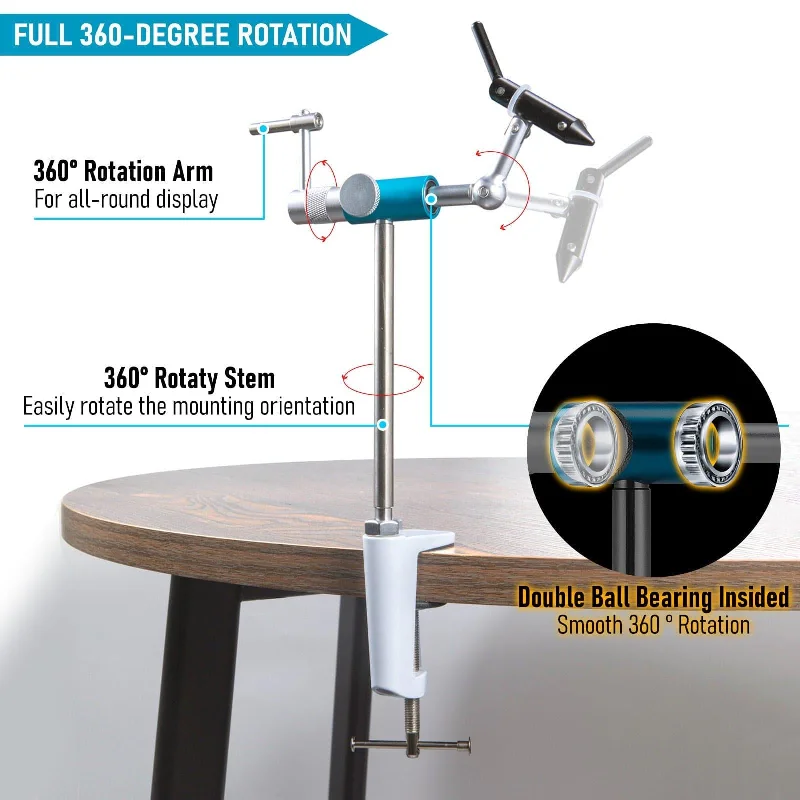

- FULL 360-DEGREE ROTATION. Ball Bearings are loaded to both end of main shaft to provide smooth 360 ° rotation. The long handle enables quick, easy and precise angle adjustment. Front and rear big-knob screw design makes it easy to adjust and provides better tightness.

- STRONG HOOK HOLDING POWER. Adopted heat treatment technology on wider and deeper profile, which greatly improves the hardness and stability, these Jaws hold hooks sized from 28 to 10/0 like a rock, making one vise for all types of flies tying possible.

- Optional Base Available. Featuring extra-long T-shaped screw, the vise can be clamped on the desktop effortlessly. C-clamp opening distance is 5.5cm/ 2.17in for compatible with all desks and tables. Hex nut design delivers easily change of the vise angle at any time, and it can be easily disassembled to replace the base. Vise’s offer with a 5 x 8” pedestal base is now available, makes it an ideal travel kit.

- FOR BEGINNER AND EXPERIENCED. Rotary vise designed for optimal tying efficiency and ease of adjustment. Even the slightest discomfort detected from the test was revised, allows you to maneuver the fly without taking it out of the vise, making it easier and taking less time to tie your flies.

Tips:

Here's a brief guide on how to care for your fly tying vise:

1.Regular Cleaning: After each tying session, use a soft-bristled brush or a can of compressed air to remove any loose materials, such as feathers, fur, or thread scraps, from the jaws and other parts of the vise

2.Dust Removal: Gently wipe down the vise with a clean, dry cloth or a microfiber cloth to remove dust and debris.

3.Lubrication: Apply a small amount of lightweight machine oil or a specialized vise lubricant to the moving parts, such as the rotation mechanism and screw threads, to keep them functioning smoothly.

4.Check Jaws and Screw Tightness: Regularly inspect the jaws to ensure they are clean and free of rust or corrosion.

5.Replace Worn Parts: Over time, parts like the jaw inserts might wear out. Replace them as needed to maintain the vise’s grip strength and protect your hooks.

6.Follow Manufacturer's Instructions: Always refer to the manufacturer's instructions for specific care and maintenance guidance, as different vises may have unique requirements